Introduction to Robotics and Automation

Robotics and automation trends are rapidly transforming the way we live, work, and interact with technology. At its core, robotics refers to the design, construction, and operation of robots, while automation is the use of technology to perform tasks without human intervention. Together, these technologies are driving innovation across industries, making processes faster, more efficient, and increasingly intelligent.

Today, robotics and automation are not limited to manufacturing plants. They are reshaping healthcare, logistics, agriculture, and even everyday consumer applications. From AI-powered surgical robots to self-driving delivery drones, the influence of robotics and automation trends can be seen in nearly every sector.

The key drivers of this revolution include advances in artificial intelligence (AI), machine learning (ML), Internet of Things (IoT), and cloud computing. These technologies enable robots and automated systems to operate intelligently, adapt to changing conditions, and perform complex tasks with high precision.http://futuretechfrontier.com

Why are robotics and automation trends important?

- Increased Productivity: Automated systems can operate 24/7 without fatigue, dramatically improving output.

- Cost Efficiency: Robots reduce human errors, lower operational costs, and optimize resource usage.

- Safety and Precision: Automation minimizes risks in dangerous environments, from chemical plants to construction sites.

- Innovation: Continuous advancements in AI and robotics foster new applications that were previously impossible.

Industries Leading the Adoption:

- Manufacturing: Smart factories and Industry 4.0 initiatives.

- Healthcare: Robotic surgery, diagnostic automation, and patient monitoring.

- Logistics and Warehousing: Automated inventory management and delivery drones.

- Agriculture: Robotics for planting, harvesting, and crop monitoring.

- Consumer Technology: Smart home devices and personal assistant robots.

As businesses and consumers continue to adopt these technologies, robotics and automation trends are set to reshape the global economy. According to a report by Markets and Markets, the robotics market is projected to reach $214 billion by 2026, driven by rising demand in healthcare, manufacturing, and logistics.

By understanding these trends, companies can stay ahead of the curve, innovate faster, and improve efficiency, while individuals can prepare for a future increasingly influenced by automated systems.

This section gives a comprehensive introduction, highlights why robotics and automation trends matter, and sets the stage for a deeper dive into current trends.

Current Robotics and Automation Trends

The landscape of robotics and automation is constantly evolving, driven by technological innovations, AI integration, and the growing demand for efficiency. Staying updated on these trends is crucial for businesses, engineers, and tech enthusiasts who want to leverage automation effectively. Here’s a detailed look at the most important robotics and automation trends in 2026:

AI-Powered Robotics

Artificial Intelligence (AI) is transforming traditional robots into intelligent machines capable of learning, adapting, and making decisions. Unlike conventional robots that follow pre-programmed commands, AI-powered robots can analyze data, detect patterns, and optimize their actions in real-time.

Examples:

- Manufacturing: AI robots monitor production lines, detect defects, and adjust processes automatically.

- Healthcare: Surgical robots use AI to assist surgeons with precision, reducing risks during operations.

- Service Industry: AI robots in hotels and restaurants can interact with customers, provide assistance, and even learn preferences over time.

Case Study:

Siemens implemented AI-driven robots in their smart factories, resulting in a 20% increase in production efficiency and a 15% reduction in waste.

Collaborative Robots (Cobots)

Cobots are designed to work side by side with humans, complementing human labor rather than replacing it. These robots are equipped with sensors and AI to ensure safe and efficient collaboration.

Key Benefits of Cobots:

- Enhance worker productivity without replacing jobs.

- Perform repetitive or hazardous tasks, reducing injury risks.

- Easily programmable for small- and medium-scale operations.

Industries Leading Cobot Adoption:

- Electronics assembly.

- Automotive manufacturing.

- Pharmaceutical production.

Industrial Automation Advancements

The rise of Industry 4.0 has accelerated the adoption of robotics in industrial automation. Factories are becoming “smart factories” where machines communicate with each other, track performance, and optimize operations automatically.

Examples of Industrial Automation Trends:

- Automated assembly lines using robotic arms.

- Real-time quality control via AI-based visual inspection.

- Predictive maintenance powered by IoT sensors.

Stat: According to McKinsey, fully automated factories can increase productivity by 30–40% while reducing operational costs significantly.

Autonomous Vehicles and Drones

Robotics and automation trends are not limited to factories—they are transforming transportation and logistics. Autonomous vehicles and drones are revolutionizing delivery, warehousing, and even ride-hailing services.

Key Applications:

- Self-driving cars: Reducing accidents and improving traffic efficiency.

- Delivery drones: Fast, contactless delivery of parcels, medical supplies, and groceries.

- Warehouse automation: Robots transport goods, manage inventory, and optimize storage.

Case Study: Amazon Robotics uses autonomous mobile robots in warehouses to increase order fulfillment speed by 50%, setting a global standard for automated logistics.

Robotics in Healthcare

Healthcare is one of the fastest-growing sectors for robotics and automation. Beyond surgical assistance, robots now support rehabilitation, diagnostics, and patient care.

Applications:

- Robotic exoskeletons for mobility-impaired patients.

- Automated pharmacy dispensing systems.

- AI-powered diagnostic robots analyzing imaging data.

Impact: According to a PwC report, automation in healthcare could save $150 billion annually globally by reducing errors and streamlining workflows.

Summary Table: Key Robotics and Automation Trends

| Trend | Key Applications | Benefits | Example/Statistic |

|---|---|---|---|

| AI-Powered Robotics | Manufacturing, healthcare, service | Intelligent decision-making, efficiency | Siemens AI robots increased productivity by 20% |

| Collaborative Robots (Cobots) | Electronics, automotive, pharma | Safety, productivity, human collaboration | Cobots reduce repetitive task fatigue by 40% |

| Industrial Automation | Smart factories, assembly lines | Cost reduction, predictive maintenance | McKinsey: 30–40% productivity increase |

| Autonomous Vehicles & Drones | Delivery, logistics | Speed, safety, efficiency | Amazon warehouse robots: 50% faster order fulfillment |

| Healthcare Robotics | Surgery, rehabilitation, diagnostics | Precision, reduced errors | PwC: $150B potential annual savings |

This section gives readers a deep understanding of current robotics and automation trends, their real-world applications, and industry impact.

Emerging Technologies Shaping Robotics and Automation

As robotics and automation trends evolve, several emerging technologies are accelerating innovation and expanding the capabilities of automated systems. These technologies are enabling robots to operate smarter, faster, and more efficiently, reshaping industries and everyday life.

Artificial Intelligence and Machine Learning

AI and machine learning (ML) are the backbone of modern robotics, transforming traditional machines into intelligent systems capable of learning, predicting, and self-optimizing.

Key Applications in Robotics:

- Predictive Maintenance: AI analyzes sensor data to detect potential failures before they happen, reducing downtime in factories.

- Autonomous Decision-Making: Robots in warehouses and logistics can adjust routes and schedules based on real-time conditions.

- Enhanced Perception: Machine learning allows robots to recognize objects, detect defects, and respond to dynamic environments.

Example:

Fanuc, a leading robotics company, uses AI to enable industrial robots to learn from human operators, improving precision and reducing errors by up to 30%.

Internet of Things (IoT) Integration

IoT devices connect robots to networks, enabling real-time monitoring, data collection, and smart decision-making. Integration of IoT sensors ensures automation systems are highly adaptive and connected across industries.

Benefits of IoT in Robotics:

- Continuous monitoring of machinery and automated systems.

- Optimization of energy consumption and resource allocation.

- Real-time updates on production performance and maintenance needs.

Example:

Smart factories use IoT-enabled sensors to track assembly line operations, allowing managers to detect bottlenecks instantly and improve efficiency by 25%.

5G and Edge Computing

The rollout of 5G networks is transforming robotics by providing ultra-fast, low-latency communication between machines and cloud systems. Coupled with edge computing, data can be processed near the source, enabling real-time decision-making for complex automation tasks.

Applications:

- Autonomous vehicles coordinating in traffic networks.

- Remote-controlled medical robots performing surgeries across cities.

- Real-time factory automation with minimal delays.

Fact: According to GSMA, 5G adoption in industrial automation is expected to boost productivity by up to 20% in connected smart factories.

Cloud Robotics

Cloud robotics leverages cloud computing to provide robots with access to vast computational power, shared data, and collaborative learning opportunities. Instead of relying solely on onboard computing, robots can offload complex tasks to the cloud.

Advantages:

- Access to global datasets for machine learning and AI.

- Remote updates and software upgrades without downtime.

- Collaborative learning across multiple robots in different locations.

Example:

RoboEarth, a research project, connects robots globally via cloud platforms, allowing them to share knowledge and learn from each other, accelerating innovation in automation.

Emerging Robotics Technology in Action

| Technology | Application | Benefits | Example |

|---|---|---|---|

| AI & Machine Learning | Predictive maintenance, decision-making | Smarter robots, error reduction | Fanuc AI-enabled industrial robots reduce errors by 30% |

| IoT Integration | Smart factories, real-time monitoring | Efficiency, adaptive automation | IoT sensors improve production efficiency by 25% |

| 5G & Edge Computing | Autonomous vehicles, remote surgery | Low latency, fast data processing | Connected factories boost productivity by 20% |

| Cloud Robotics | Collaborative learning, remote updates | Scalability, global knowledge sharing | RoboEarth project enables robots to learn from each other worldwide |

Key Insight:

The combination of AI, IoT, 5G, edge computing, and cloud robotics is reshaping the very definition of automation, moving it from simple mechanization to intelligent, adaptive systems capable of solving complex problems.

These emerging technologies are not just trends, but the foundation for future robotics and automation innovations, creating a smarter, more connected world across industries.

Benefits of Robotics and Automation

Adopting robotics and automation trends offers numerous advantages across industries, transforming how businesses operate, improving productivity, and enhancing overall efficiency. Below, we explore the key benefits in detail.

1. Increased Productivity and Efficiency

Automation allows machines to operate continuously without fatigue, significantly boosting productivity. Robots can perform repetitive tasks with high precision, freeing humans to focus on creative, strategic, or complex work.

Example:

- Tesla’s production line uses robotic arms for welding and assembly, enabling the company to produce over 1,000 cars per day with consistent quality.

- In warehouses, automated systems can pick, sort, and package thousands of items per hour, a task that would take human workers much longer.

Fact: According to McKinsey, companies that adopt industrial automation can experience productivity gains of 20–40%, depending on the level of integration.

2. Reduction in Operational Costs

Though the initial investment in robotics and automation can be high, long-term cost savings are substantial. Robots reduce errors, lower wastage, and minimize the need for repetitive labor.

Examples of Cost Efficiency:

- Manufacturing robots can reduce material waste by 15–20% through precise handling.

- Automated inventory systems reduce storage and logistics costs by optimizing space and tracking stock levels accurately.

Case Study:

Siemens implemented automated production lines and reported $12 million in annual savings due to reduced errors and optimized workflows.

3. Improved Safety and Risk Reduction

Robotics and automation trends enhance workplace safety by handling dangerous, repetitive, or physically demanding tasks. This reduces workplace injuries and occupational hazards.

Applications:

- Robots in chemical plants handle toxic substances safely.

- Construction robots lift heavy materials, minimizing strain on human workers.

- Autonomous drones inspect hazardous areas like pipelines and bridges, reducing human risk.

Fact: The Occupational Safety and Health Administration (OSHA) estimates that automation can reduce workplace injuries by 25–30% in high-risk industries.

4. Enhanced Precision and Quality Control

Robots excel at performing tasks with incredible accuracy, ensuring consistent quality that is often difficult for humans to maintain over long periods.

Examples:

- Surgical robots provide millimeter-precision during operations, minimizing complications.

- Industrial robots assemble electronic devices with exact tolerances, reducing defective products.

- Automated quality inspection using AI-powered cameras detects defects invisible to the human eye.

Statistic: In electronics manufacturing, automated inspection systems have reduced product defects by up to 50%.

5. Opportunities for Human-Robot Collaboration

Robotics and automation do not always replace human workers—they enhance their capabilities. Collaborative robots (cobots) work alongside humans, increasing efficiency and allowing humans to focus on tasks requiring creativity, judgment, and decision-making.

Example:

- Ford’s automotive plants use cobots to assist assembly workers, combining human dexterity and robotic precision for better productivity.

- Warehouses use cobots to lift and transport goods while humans manage logistics and planning.

Summary Table: Key Benefits of Robotics and Automation

| Benefit | Description | Example/Impact |

|---|---|---|

| Increased Productivity | Operates 24/7, faster output | Tesla produces 1,000+ cars/day |

| Cost Reduction | Lowers errors and waste | Siemens saved $12M annually |

| Safety Enhancement | Reduces workplace injuries | Drones inspect hazardous pipelines |

| Precision & Quality | High accuracy, consistent output | Defect rate reduced by 50% in electronics |

| Human-Robot Collaboration | Complements human work | Cobots assist Ford assembly line |

Key Insight:

The adoption of robotics and automation trends improves efficiency, reduces costs, enhances safety, and ensures superior quality. These benefits are not just theoretical—they are measurable and directly impact business profitability, scalability, and innovation potential.

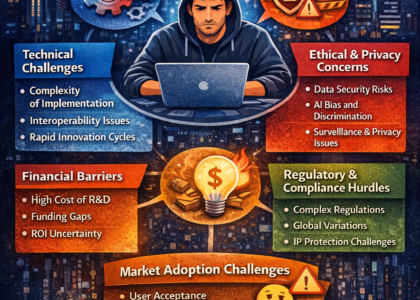

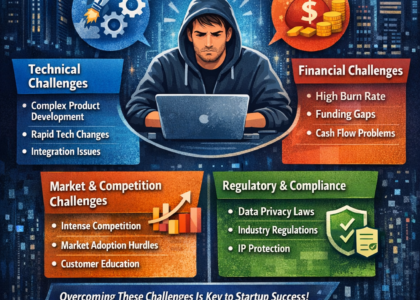

Challenges in Robotics and Automation

While robotics and automation trends bring significant benefits, implementing these technologies is not without challenges. Understanding these obstacles helps organizations plan better, mitigate risks, and ensure a smooth adoption process.

1. High Implementation Costs

One of the most significant challenges of robotics and automation is the initial investment. Purchasing robotic equipment, integrating it into existing systems, and training staff can require substantial capital.

Examples:

- Advanced industrial robots can cost $50,000 to $150,000 each, depending on functionality and sophistication.

- Implementing fully automated smart factories may require millions in infrastructure upgrades.

Fact: According to Boston Consulting Group, the average ROI for industrial automation may take 3–5 years, depending on scale and application.

2. Technical Complexity and Maintenance

Robotics systems are highly sophisticated, often requiring specialized knowledge for installation, operation, and maintenance. Technical issues can lead to downtime, reducing productivity if not managed properly.

Challenges Include:

- Integrating robots with legacy systems.

- Managing software updates, firmware, and AI model tuning.

- Ensuring compatibility across multiple devices and automation platforms.

Example: Manufacturing plants often employ dedicated robotics engineers to monitor and troubleshoot automated production lines.

3. Workforce Displacement Concerns

The fear that robots will replace human workers is one of the biggest societal challenges. While automation improves efficiency, it can lead to job displacement in certain sectors, particularly in repetitive or manual roles.

Reality Check:

- Automation often redefines roles rather than completely eliminating them. For example, human workers may move into robot supervision, programming, or maintenance roles.

- A report by World Economic Forum predicts that by 2026, automation could displace 85 million jobs but create 97 million new ones, mostly in tech, AI, and robotics-related fields.

4. Cybersecurity Risks

As robotics and automation systems become more connected through IoT and cloud platforms, they become targets for cyberattacks. Vulnerabilities in automation systems can lead to data breaches, operational disruptions, or safety hazards.

Examples:

- Industrial control systems in factories are increasingly targeted by hackers.

- Autonomous vehicles and drones are susceptible to hijacking or data manipulation.

Solution: Strong cybersecurity protocols, encrypted communications, and continuous monitoring are essential to safeguard automated systems.

5. Ethical and Regulatory Considerations

The rise of AI-powered robotics introduces ethical dilemmas that must be addressed. Decisions made by autonomous robots can have serious consequences, raising questions about responsibility, accountability, and fairness.

Key Concerns:

- Who is responsible if an autonomous robot causes harm?

- How to prevent bias in AI-powered decision-making robots?

- Ensuring compliance with international regulations and safety standards.

Fact: The European Union is working on AI regulations for robotics, focusing on transparency, safety, and human oversight.

Summary Table: Challenges in Robotics and Automation

| Challenge | Description | Example/Impact |

|---|---|---|

| High Costs | Expensive hardware and integration | Robots cost $50k–$150k each; smart factory upgrades in millions |

| Technical Complexity | Requires skilled staff and maintenance | Dedicated robotics engineers needed |

| Workforce Displacement | Automation may replace some jobs | WEF: 85M jobs displaced, 97M new created by 2026 |

| Cybersecurity Risks | Connected systems vulnerable to attacks | Hackers can target industrial robots or autonomous vehicles |

| Ethical & Regulatory Issues | AI decision-making accountability | EU developing AI safety regulations |

Key Insight:

While robotics and automation trends promise efficiency and innovation, businesses must address these challenges proactively. Balancing costs, workforce training, cybersecurity, and ethical compliance is critical to maximize the benefits of automation while minimizing risks.

Future Robotics and Automation Trends

As technology advances, robotics and automation trends are expected to evolve dramatically, impacting industries, businesses, and daily life. The future will not only bring more sophisticated machines but also smarter, more collaborative, and sustainable solutions.

1. Smart Factories and Industry 5.0

The future of industrial automation goes beyond Industry 4.0. Industry 5.0 focuses on human-centric automation, combining the intelligence of machines with human creativity.

Key Features:

- Robots working collaboratively with humans for customized production.

- Real-time optimization using AI, IoT, and cloud robotics.

- Increased flexibility for personalized manufacturing.

Example:

Companies like ABB and Schneider Electric are developing smart factories where cobots assist humans in assembling customized products, improving both efficiency and worker satisfaction.

2. Robotics in Everyday Life

Robotics and automation trends are not limited to factories—they are increasingly entering homes and consumer spaces.

Examples of Consumer Robotics:

- Home automation robots: Vacuum robots, lawn-mowing robots, and personal assistants.

- Service robots: In hotels, airports, and restaurants for customer service.

- Healthcare robots at home: Assistance for elderly or mobility-impaired individuals.

Impact:

According to Statista, the global consumer robotics market is projected to reach $16 billion by 2027, reflecting the growing adoption of robotics in daily life.

3. Robotics and Sustainable Technology

The next generation of robotics emphasizes sustainability, reducing environmental impact while maintaining efficiency.

Applications:

- Energy-efficient industrial robots and automated systems.

- Automated recycling and waste management robots.

- Precision agriculture robots that reduce water and fertilizer use.

Example:

John Deere’s autonomous agricultural robots use AI and precision sensors to optimize irrigation and fertilizer application, reducing chemical use by up to 30%.

4. Predictions for the Next 5–10 Years

What to Expect in Robotics and Automation:

- Advanced AI integration: Robots will handle more complex tasks with minimal human intervention.

- Expansion into new industries: Retail, hospitality, and education will adopt robotics more widely.

- Workforce transformation: Humans and robots will collaborate in hybrid work models.

- Global adoption of autonomous vehicles and drones: Transforming logistics, transport, and delivery services.

- Ethical AI frameworks: Regulation will ensure safe and responsible robotic behavior.

Fact: A report by Markets and Markets predicts the global robotics market will grow to $214 billion by 2026, driven by industrial, healthcare, and consumer robotics adoption.

Summary Table: Future Robotics and Automation Trends

| Trend | Application | Benefits | Example/Impact |

|---|---|---|---|

| Smart Factories (Industry 5.0) | Human-robot collaboration in manufacturing | Personalized production, efficiency | ABB smart factories increase output with cobots |

| Consumer Robotics | Home robots, personal assistants | Convenience, daily task automation | Consumer robotics market $16B by 2027 |

| Sustainable Technology | Precision agriculture, recycling robots | Eco-friendly operations, resource optimization | John Deere reduces chemical use by 30% |

| AI Integration | Autonomous tasks across industries | Smarter decision-making, minimal human input | AI-powered logistics robots improve delivery efficiency |

| Autonomous Vehicles & Drones | Transport, delivery, logistics | Safety, speed, reduced labor | Amazon drones: faster, contactless delivery |

Key Insight:

The future of robotics and automation is human-centered, sustainable, and increasingly intelligent. Organizations that adopt these innovations will gain a competitive edge, while society benefits from safer, more efficient, and environmentally conscious automation solutions.