Introduction

Industrial technology is evolving at an unprecedented pace, shaping the future of manufacturing, energy, logistics, and even healthcare. Industrial tech advancements such as automation, artificial intelligence (AI), the Industrial Internet of Things (IIoT), and robotics are revolutionizing how businesses operate, enabling greater efficiency, precision, and scalability. From smart factories to predictive maintenance systems, the integration of advanced technologies is transforming industries worldwide.

Modern industries are no longer limited by traditional production methods. Innovations in digital twins, 3D printing, and advanced robotics are enabling manufacturers to simulate processes, prototype products rapidly, and optimize complex systems in real-time. These technologies not only increase productivity but also reduce operational costs, enhance safety, and support sustainability initiatives.

The demand for industrial tech advancements continues to grow as businesses face global competition, resource constraints, and the need for more agile production processes. By embracing these technologies, companies can stay ahead of the curve, improve product quality, and respond faster to market changes.

In this article, we will explore the most important industrial tech advancements, the benefits they bring, the challenges of adoption, future trends, and real-world case studies that illustrate their transformative impact. Whether you are a business leader, engineer, or tech enthusiast, this comprehensive guide will provide insights into how technology is reshaping industry today and in the years to come.http://futuretechfrontier.com

The Evolution of Industrial Technology

The story of industrial progress is one of continuous innovation, where each technological leap has reshaped society and the way goods are produced. Industrial tech advancements are not a sudden phenomenon—they are the result of centuries of development, from mechanization to smart manufacturing.

From Traditional Industry to Industry 4.0

The industrial landscape has undergone four major revolutions:

- Industry 1.0 – Mechanization: Steam engines and water-powered machinery revolutionized production in the 18th century.

- Industry 2.0 – Mass Production: The introduction of electricity and assembly lines enabled high-volume production in the early 20th century.

- Industry 3.0 – Automation: Digital electronics and programmable logic controllers (PLCs) automated many tasks, reducing human error and improving efficiency.

- Industry 4.0 – Smart Manufacturing: Today, industrial tech advancements focus on connectivity, intelligence, and data-driven decision-making. This era integrates AI, robotics, IIoT, and cloud computing to create fully connected, autonomous, and highly efficient production environments.

These transformations have drastically increased production efficiency, lowered costs, and allowed businesses to adapt to changing market demands more rapidly than ever before.

Key Drivers of Modern Industrial Innovation

Several technologies are driving the current wave of industrial tech advancements:

- Internet of Things (IIoT): Connected sensors and devices enable real-time monitoring and predictive maintenance, reducing downtime and improving operational efficiency.

- Artificial Intelligence & Machine Learning: AI systems analyze massive datasets to optimize production, detect defects, and automate decision-making.

- Big Data Analytics: Advanced analytics allow companies to identify patterns, forecast demand, and streamline supply chains.

- Cloud & Edge Computing: Cloud platforms centralize data storage and analysis, while edge computing processes data locally for faster insights and lower latency.

Fact: According to a 2024 McKinsey report, companies implementing Industry 4.0 technologies have achieved a 20–30% increase in productivity and up to 25% reduction in operational costs, highlighting the transformative impact of modern industrial technology.

Cutting-Edge Industrial Tech Advancements

Modern industries are witnessing an explosion of innovations that are redefining how products are designed, manufactured, and delivered. Industrial tech advancements are no longer confined to automation—they encompass AI, IIoT, robotics, advanced manufacturing methods, and cybersecurity solutions. These technologies are creating smarter, safer, and more efficient industrial environments.

Automation and Robotics

Automation and robotics remain at the forefront of industrial innovation. Industrial robots perform repetitive or hazardous tasks with precision, while collaborative robots (cobots) work safely alongside humans.

Key applications:

- Manufacturing assembly lines: Robots improve speed and accuracy in automotive and electronics production.

- Logistics and warehousing: Automated guided vehicles (AGVs) and drones optimize storage and inventory management.

- Hazardous environments: Robots handle dangerous tasks in chemical plants, mines, and nuclear facilities.

Case Study: Automotive manufacturers like Tesla and Toyota use advanced robotics for assembly and welding, reducing production errors by up to 70% while increasing throughput.

Artificial Intelligence and Machine Learning

AI and machine learning (ML) are transforming decision-making and operational efficiency. By analyzing vast amounts of industrial data, AI systems enable predictive maintenance, quality control, and supply chain optimization.

Key applications:

- Predictive maintenance: AI predicts equipment failures before they occur, reducing downtime and repair costs.

- Automated quality control: ML algorithms detect defects faster than human inspectors.

- Smart supply chains: AI forecasts demand, optimizes inventory, and reduces waste.

Fact: According to PwC (2023), manufacturers using AI-driven predictive maintenance report 30–40% reduction in unplanned downtime.

Industrial Internet of Things (IIoT)

IIoT connects machinery, sensors, and devices to the internet, enabling real-time monitoring and control. This connectivity allows organizations to collect actionable insights and optimize processes continuously.

Benefits of IIoT:

- Real-time monitoring of production lines and equipment health

- Remote diagnostics and faster troubleshooting

- Energy management and resource optimization

Example: GE’s Predix platform integrates IIoT sensors across industrial machines to monitor performance and predict maintenance needs, saving millions in operational costs.

Advanced Manufacturing Technologies

Emerging manufacturing technologies are reshaping prototyping, production, and design.

Key technologies include:

- 3D printing / additive manufacturing: Enables rapid prototyping and custom production at lower costs.

- Digital twins: Virtual replicas of industrial systems allow testing, optimization, and simulation before implementation.

- Nanotechnology and advanced materials: Enhance durability, efficiency, and performance of industrial products.

Example: Boeing uses 3D printing to produce lightweight aircraft components, reducing weight by up to 50%, which improves fuel efficiency and lowers costs.

Cybersecurity in Industrial Tech

With increased connectivity comes increased risk. Securing industrial systems is critical to prevent data breaches, ransomware attacks, and operational disruptions.

Best practices in industrial cybersecurity:

- Implement network segmentation and secure IIoT devices

- Regular firmware and software updates

- Continuous monitoring and anomaly detection

Fact: The 2021 Colonial Pipeline cyberattack demonstrated how vulnerable critical industrial infrastructure can be without robust cybersecurity measures.

Benefits of Industrial Tech Advancements

The adoption of modern industrial tech advancements delivers transformative benefits across productivity, cost efficiency, workforce safety, and sustainability. By integrating automation, AI, IIoT, and advanced manufacturing techniques, industries are achieving unprecedented operational performance and competitive advantage.

Increased Efficiency and Productivity

Modern industrial technologies streamline processes and reduce bottlenecks, resulting in faster production cycles and higher throughput.

Key improvements include:

- Automation: Robots and AI-driven systems perform repetitive tasks more accurately and continuously than humans.

- Predictive Maintenance: Sensors detect potential equipment failures, preventing costly unplanned downtime.

- Real-Time Monitoring: IIoT devices provide instant insights, allowing immediate adjustments to optimize operations.

Fact: According to a 2023 McKinsey report, manufacturers using Industry 4.0 technologies experience a 20–30% increase in production efficiency.

Cost Savings and Resource Optimization

Investing in advanced industrial technologies leads to significant cost reductions and resource efficiency:

- Energy Management: Smart sensors and AI optimize energy consumption in factories.

- Waste Reduction: AI-driven quality control minimizes defective products and scrap.

- Supply Chain Optimization: Real-time tracking and predictive analytics reduce inventory costs and transportation waste.

Example: Siemens implemented IIoT and AI solutions in their electronics manufacturing plants, reducing energy usage by 15% and saving millions annually on operational costs.

Safety and Workforce Empowerment

Industrial tech advancements enhance workplace safety and empower employees to focus on higher-value tasks:

- Hazard Reduction: Robots handle dangerous tasks such as heavy lifting, chemical handling, and high-temperature operations.

- Upskilling Workers: Employees are trained to manage and maintain advanced machinery, boosting skills and job satisfaction.

- Remote Operations: Smart devices and AI allow monitoring of industrial processes without exposing workers to hazardous conditions.

Case Study: In chemical plants, automated robotic systems now perform high-risk operations, leading to a 40% decrease in workplace accidents.

Sustainability and Environmental Impact

Modern industrial technology also contributes to eco-friendly practices and sustainability goals:

- Emission Reduction: AI and smart systems optimize energy use, lowering greenhouse gas emissions.

- Green Manufacturing: 3D printing reduces material waste and allows on-demand production.

- Circular Economy Initiatives: Advanced tech enables recycling and reuse of industrial materials.

Fact: According to the World Economic Forum, companies adopting Industry 4.0 technologies can reduce carbon emissions in manufacturing by up to 20%.

Challenges in Adopting Industrial Tech Advancements

While the benefits of industrial tech advancements are substantial, organizations face several challenges and barriers when integrating these technologies. Understanding these obstacles is essential for developing effective strategies and ensuring a successful digital transformation.

High Implementation Costs

One of the primary challenges is the significant investment required to adopt advanced technologies.

- Equipment Costs: Industrial robots, automated machinery, and IIoT sensors require high upfront capital.

- Software and Platform Investments: AI analytics platforms, digital twin software, and cloud computing services add additional expenses.

- Training and Support: Employees need specialized training to operate and maintain new technologies effectively.

Fact: According to Deloitte, 40% of manufacturers cite initial investment cost as a key barrier to Industry 4.0 adoption. Organizations must carefully evaluate ROI and prioritize solutions that deliver measurable value.

Integration with Legacy Systems

Many industrial facilities rely on legacy equipment and processes, which can complicate the integration of new technologies.

- Compatibility Issues: Older machines may lack the connectivity or data interfaces required for modern systems.

- Operational Disruption: Retrofitting legacy systems can cause temporary production slowdowns.

- Data Silos: Disconnected systems make centralized monitoring and analysis difficult.

Solution: Gradual implementation using hybrid systems, edge computing, and middleware solutions can bridge the gap between old and new technology, ensuring smoother transitions.

Workforce Adaptation and Skills Gap

Advanced industrial technologies require highly skilled workers, leading to a skills gap in many organizations.

- Upskilling Requirements: Employees need training in AI, robotics, IIoT, and cybersecurity.

- Resistance to Change: Staff may be hesitant to adopt new workflows or automation tools.

- Talent Shortage: There is a growing demand for engineers and technicians proficient in Industry 4.0 technologies.

Example: A survey by the World Economic Forum revealed that over 50% of industrial companies struggle to find employees with digital skills, highlighting the need for continuous education and workforce development.

Cybersecurity and Data Privacy Concerns

Increased connectivity exposes industrial systems to cyber threats.

- Vulnerable IIoT Devices: Connected sensors and machinery can be entry points for attackers.

- Data Breaches: Sensitive operational and design data may be at risk.

- Regulatory Compliance: Companies must comply with industry-specific cybersecurity and privacy standards.

Case Study: The Colonial Pipeline cyberattack in 2021 demonstrated the catastrophic impact of industrial cybersecurity breaches, emphasizing the need for robust network segmentation, monitoring, and incident response plans.

Future Trends in Industrial Tech Advancements

As technology continues to evolve, the landscape of industry is set for even more transformative advancements. The next wave of industrial tech advancements will focus on automation, AI, sustainability, and interconnected smart systems, reshaping production, logistics, and overall operational strategy.

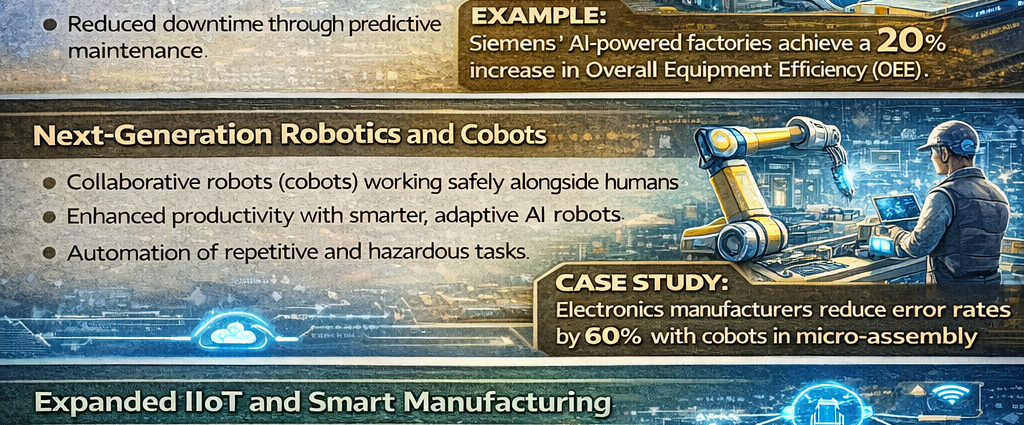

AI and Autonomous Factories

Artificial intelligence is powering the concept of fully autonomous factories, where production lines can operate with minimal human intervention.

- Self-Optimizing Systems: AI analyzes real-time data to optimize workflow and machine performance.

- Autonomous Decision-Making: Predictive algorithms manage scheduling, inventory, and maintenance without human input.

- Reduced Downtime: AI predicts failures before they occur, enabling preemptive repairs and uninterrupted operations.

Example: Siemens’ AI-powered factories use predictive analytics and automation to optimize production cycles, achieving a 20% increase in overall equipment efficiency (OEE).

Next-Generation Robotics and Cobots

Robotics technology is becoming smarter and more collaborative, enabling seamless human-robot interaction.

- Cobots in Operations: Collaborative robots work alongside humans for precision tasks.

- Adaptive AI Robots: Machines learn and adapt to changes in production requirements.

- Enhanced Productivity: Automation of repetitive and dangerous tasks frees human workers for strategic work.

Case Study: In electronics manufacturing, cobots assist in micro-assembly, reducing error rates by up to 60% while maintaining safety in compact workspaces.

Expanded IIoT and Smart Manufacturing

The Industrial Internet of Things (IIoT) will continue to drive connected, data-driven operations.

- Real-Time Monitoring Across Facilities: Sensors collect and transmit operational data instantly.

- Predictive Analytics: AI algorithms analyze trends to anticipate maintenance, optimize energy use, and prevent production disruptions.

- Interconnected Global Operations: Factories and warehouses worldwide communicate in real-time, improving supply chain efficiency.

Fact: According to Gartner, by 2026, over 75% of industrial manufacturers will have adopted IIoT platforms to drive operational intelligence.

Sustainable Industrial Innovations

Sustainability is a critical driver of future industrial technology adoption.

- Circular Economy Practices: Recycling and reuse of industrial materials reduce environmental impact.

- Energy-Efficient Operations: Smart sensors and AI reduce energy consumption across plants.

- Renewable Energy Integration: Factories increasingly incorporate solar, wind, and other clean energy sources into operations.

Example: Bosch has implemented smart energy management systems across its manufacturing plants, reducing CO2 emissions by over 20% while maintaining production efficiency.

Comments are closed, but trackbacks and pingbacks are open.